NEW

ECS-F1HE335K Socket Accessories: Core Functional Technologies and Application Development CasesThe ECS-F1HE335K socket accessory is a vital component in the realm of electronics, particularly for integrated circuits (ICs) and microcontrollers. This document highlights the core functional technologies associated with socket accessories like the ECS-F1HE335K and presents application development cases that showcase their effectiveness.

Core Functional Technologies of Socket Accessories1. Interconnectivity2. Ease of Replacement3. Signal Integrity4. Thermal Management5. Compatibility6. Testing and Debugging1. Prototyping and Development2. Automotive Applications3. Consumer Electronics4. Medical Devices5. Educational Kits Application Development Cases ConclusionThe ECS-F1HE335K socket accessory exemplifies the critical role that socket technology plays in modern electronics. Its core functionalities—interconnectivity, ease of replacement, signal integrity, thermal management, compatibility, and testing capabilities—make it an invaluable component across various applications. The development cases illustrate how these sockets can enhance prototyping, reduce costs, and improve product reliability in multiple industries. As technology continues to evolve, the importance of effective socket accessories will only grow, driving innovation in electronic design and application development.

Application Development in IC Sockets for ECS-F1HE475K: Key Technologies and Success StoriesDeveloping applications for Integrated Circuits (ICs) like the ECS-F1HE475K, part of the ECS (Embedded Control Solutions) family, involves leveraging various technologies and methodologies. Below is an overview of the key technologies and notable success stories associated with application development for such devices.

Key Technologies1. Embedded Systems Programming2. Hardware Abstraction Layer (HAL)3. Communication Protocols4. Development Tools5. Power Management6. Security Features7. IoT Integration1. Automotive Applications2. Industrial Automation3. Consumer Electronics4. Healthcare Devices5. Smart Grid Solutions Success Stories ConclusionThe ECS-F1HE475K and similar ICs are integral to a wide range of applications across various industries. By leveraging key technologies such as embedded systems programming, communication protocols, and IoT integration, developers can create innovative solutions that address contemporary challenges. The success stories in automotive, industrial automation, consumer electronics, healthcare, and smart grid solutions underscore the versatility and effectiveness of these ICs in real-world applications, paving the way for future advancements in embedded technology.

S6008L Knife Connectors: Core Functional Technology and Application DevelopmentIntroduction to Knife Connectors

Knife connectors, particularly the S6008L model, are vital components in electrical and electronic systems, providing reliable and efficient connections across a variety of applications. These connectors are engineered for quick and secure connections, making them ideal for environments where space is constrained and performance is paramount. Core Functional Technology1. Design and Construction2. Electrical Performance3. Mechanical Properties4. Compatibility1. Automotive Industry2. Industrial Automation3. Consumer Electronics4. Renewable Energy Systems5. Telecommunications Application Development Cases ConclusionThe S6008L knife connector represents significant advancements in connector technology, providing robust solutions for a diverse array of applications. Its thoughtful design, superior electrical performance, and mechanical resilience make it a preferred choice across industries such as automotive, industrial automation, consumer electronics, renewable energy, and telecommunications. As technology continues to evolve, knife connectors like the S6008L will remain integral in ensuring reliable and efficient electrical connections across various sectors, supporting the ongoing push for innovation and efficiency in electrical systems.

Overview of Foil ConnectorsFoil connectors are specialized electrical connectors made from thin metal foils, designed to provide reliable electrical connections in various applications. Their unique properties and manufacturing techniques make them suitable for a wide range of industries, including consumer electronics, automotive, medical devices, telecommunications, and industrial automation.

Core Functional Technology of Foil Connectors1. Design and Structure2. Material Properties3. Manufacturing Techniques4. Electrical Performance1. Consumer Electronics2. Automotive Industry3. Medical Devices4. Telecommunications5. Industrial Automation Application Development Cases ConclusionFoil connectors represent a versatile and effective solution for a wide array of applications across multiple industries. Their unique design, material properties, and advanced manufacturing techniques contribute to their superior performance in high-frequency, high-current, and harsh environments. As technology continues to advance, the development and application of foil connectors are expected to expand, leading to innovative connectivity solutions that meet the evolving needs of various sectors.

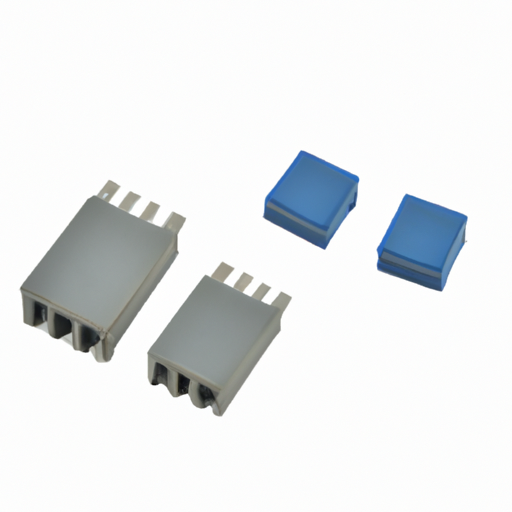

Overview of Wire-to-Board ConnectorsWire-to-board connectors are critical components in electronic systems, enabling the connection between wires and printed circuit boards (PCBs). They facilitate power and signal transmission, ensuring that various electronic components work together seamlessly. This overview highlights the core functional technologies of wire-to-board connectors and provides application development cases that demonstrate their effectiveness across different industries.

Core Functional Technologies of Wire-to-Board Connectors1. Mechanical Design2. Electrical Performance3. Material Selection4. Size and Form Factor5. Environmental Resistance1. Consumer Electronics2. Automotive Applications3. Industrial Automation4. Medical Devices5. Telecommunications Application Development Cases ConclusionWire-to-board connectors are indispensable in modern electronic systems, providing reliable connections across a wide range of applications. Their mechanical, electrical, and environmental features make them suitable for diverse industries, from consumer electronics to automotive and medical devices. As technology continues to evolve, the demand for more compact, efficient, and reliable connectors will drive innovation in this essential component category, ensuring that they remain integral to the development of advanced electronic systems.

Overview of 1N5235B-T Zener DiodeThe 1N5235B-T is a Zener diode, not a ring connector. Zener diodes are semiconductor devices that allow current to flow in the reverse direction when a specific voltage (the Zener voltage) is reached. They are widely used for voltage regulation and protection in electronic circuits. Below, we will explore the core functional technology of Zener diodes, their applications, and relevant development cases.

Core Functional Technology of Zener Diodes1. Voltage Regulation2. Reverse Breakdown3. Temperature Stability4. Low Noise5. Compact Design1. Voltage Regulation Circuits2. Overvoltage Protection3. Reference Voltage Sources4. Signal Clipping5. LED Drivers1. Power Supply Design2. Telecommunication Equipment3. Consumer Electronics4. Automotive Applications Applications of Zener Diodes Development Cases ConclusionThe 1N5235B-T Zener diode is a crucial component in various electronic applications, providing voltage regulation, overvoltage protection, and stable reference voltages. Its core functional technology, including reverse breakdown characteristics and temperature stability, makes it suitable for diverse applications in power supplies, telecommunications, consumer electronics, and automotive systems. The development cases highlight its effectiveness in enhancing performance and reliability in critical electronic systems. If you need more specific information about ring connectors or any other topic, feel free to ask!

Overview of Coaxial Connectors (RF Contacts)Coaxial connectors are critical components in radio frequency (RF) applications, enabling the connection of coaxial cables to various devices while preserving signal integrity. Their design minimizes signal loss and interference, making them indispensable in telecommunications, broadcasting, and data transmission.

Core Functional Technologies1. Impedance Matching: Coaxial connectors are engineered to match the impedance of the coaxial cable (commonly 50 or 75 ohms). This matching minimizes signal reflections and ensures optimal power transfer, which is crucial for maintaining signal quality in RF applications. 2. Shielding: The coaxial structure inherently provides excellent shielding against electromagnetic interference (EMI). This shielding is vital for maintaining signal integrity, especially in environments with high levels of electronic noise.

3. Low Insertion Loss: High-quality RF connectors are designed to exhibit low insertion loss, which is essential for preserving signal strength over long distances. This characteristic is particularly important in applications where signal degradation can lead to performance issues.

4. Durability and Reliability: Many RF connectors are built to withstand harsh environmental conditions, including extreme temperatures, moisture, and mechanical stress. This durability is crucial in applications such as aerospace and military, where reliability is paramount.

5. Ease of Use: Modern RF connectors often feature quick-connect designs, allowing for easy installation and removal without the need for specialized tools. This convenience is beneficial in both field and laboratory settings.

Application Development Cases1. Telecommunications: RF connectors are extensively used in cellular base stations, antennas, and other telecommunications equipment. The rollout of 5G networks, for instance, relies on high-performance coaxial connectors to ensure reliable and high-speed data transmission.

2. Broadcasting: In television and radio broadcasting, RF connectors are essential for connecting transmitters to antennas. The quality of these connectors directly impacts the clarity and reach of broadcast signals, making them a critical component in the broadcasting chain.

3. Aerospace and Defense: RF connectors are vital in military and aerospace applications, where they are used in radar systems, satellite communications, and electronic warfare systems. These connectors must meet stringent standards for reliability and performance under extreme conditions, including vibration and temperature fluctuations.

4. Medical Devices: In medical imaging equipment, such as MRI and ultrasound machines, RF connectors are used to connect various components while ensuring minimal signal loss and interference. The precision and reliability of these connectors are crucial for accurate diagnostics.

5. Consumer Electronics: RF connectors are also prevalent in consumer devices like televisions, set-top boxes, and gaming consoles. They facilitate the connection of antennas and other RF components, ensuring high-quality signal reception and transmission.

ConclusionCoaxial connectors (RF contacts) are integral to a wide range of industries, ensuring reliable and high-quality signal transmission. As technology advances, the design and materials used in RF connectors continue to evolve, addressing the growing demands for higher frequencies, greater bandwidth, and improved performance in modern applications. Ongoing innovations in connector technology will further enhance their capabilities, making them even more effective in diverse applications.

lang_service_time

lang_select_kefu

Yeonsin Lian